Newsletter 1

Newsletter 01/03/2024

Hello and Welcome !

As time slides toward spring, we want to welcome you to our first official newsletter. We are very excited to launch this newsletter which will keep you informed about our activities. Some of you may know us well, and some of you may have only heard of us. For those of you who collaborate with us regularly, thanks for all the great work you do. For those of you who are getting to know us, we are a specialized coating and surface treatment company, serving as both jobcoater and equipment supplier in electropplating, plasma and ion implantation technologies.

Twice a year, we'll share relevant news, information about our company, as well as important dates for upcoming events. We hope you will find it valuable and engaging !

We wish you an insightful reading.

The IONICS Team

Innovative projects at IONICS: collaborative ventures for sustainable solutions

|

IONICS is actively engaged in several projects focused on plasma technologies, each playing a role in advanced sustainable solutions. These projects entail collaborations with various partners and are often co-financed by the Walloon Research Administration. Here are five projects aimed at addressing the needs of our customers and partners. |

Engineering excellence in action

|

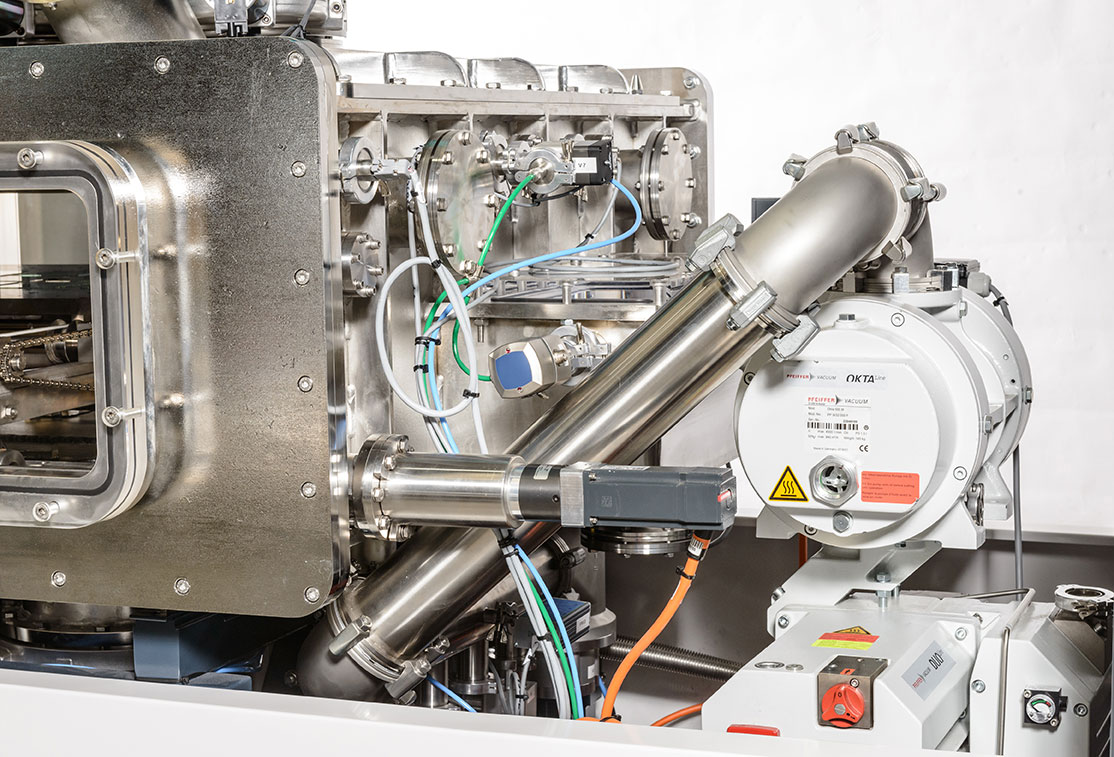

Our Team in full swing ! One year ago, IONICS presented its factory and equipment to MICHELIN team. Fast forward six months, MICHELIN entrusted IONICS with a significant order: building of a state-of-the-art R&D machine for plasma treatments. This order entails a substantial financial commitment of nearly €1 million and is scheduled for delivery in the first half of 2024. The machine designed for MICHELIN is a custom-built, stand-alone unit for vacuum surface treatments, able to reach pressure levels below 10-6 mbar, compatible with PVD, PeCVD and/or ion implantation applications, controlled by a fully-automated system offering a user-friendly interface including all the desired functionalities. Involvement, passion and business focused are the essences for our engineering departement. Apart from overseeing the construction of machines, the department also handles small-scale R&D production. Led by our Chief Technical Officer, Laurent GERON, the team ensures that the machines operate optimally and are prepared for timely delivery to customers. The team is fully committed during this crucial phase, with deadlines driving our collective determination and focus. So good news, production is running at full speed at IONICS ! |

Plasma & Ion implantation production update

|

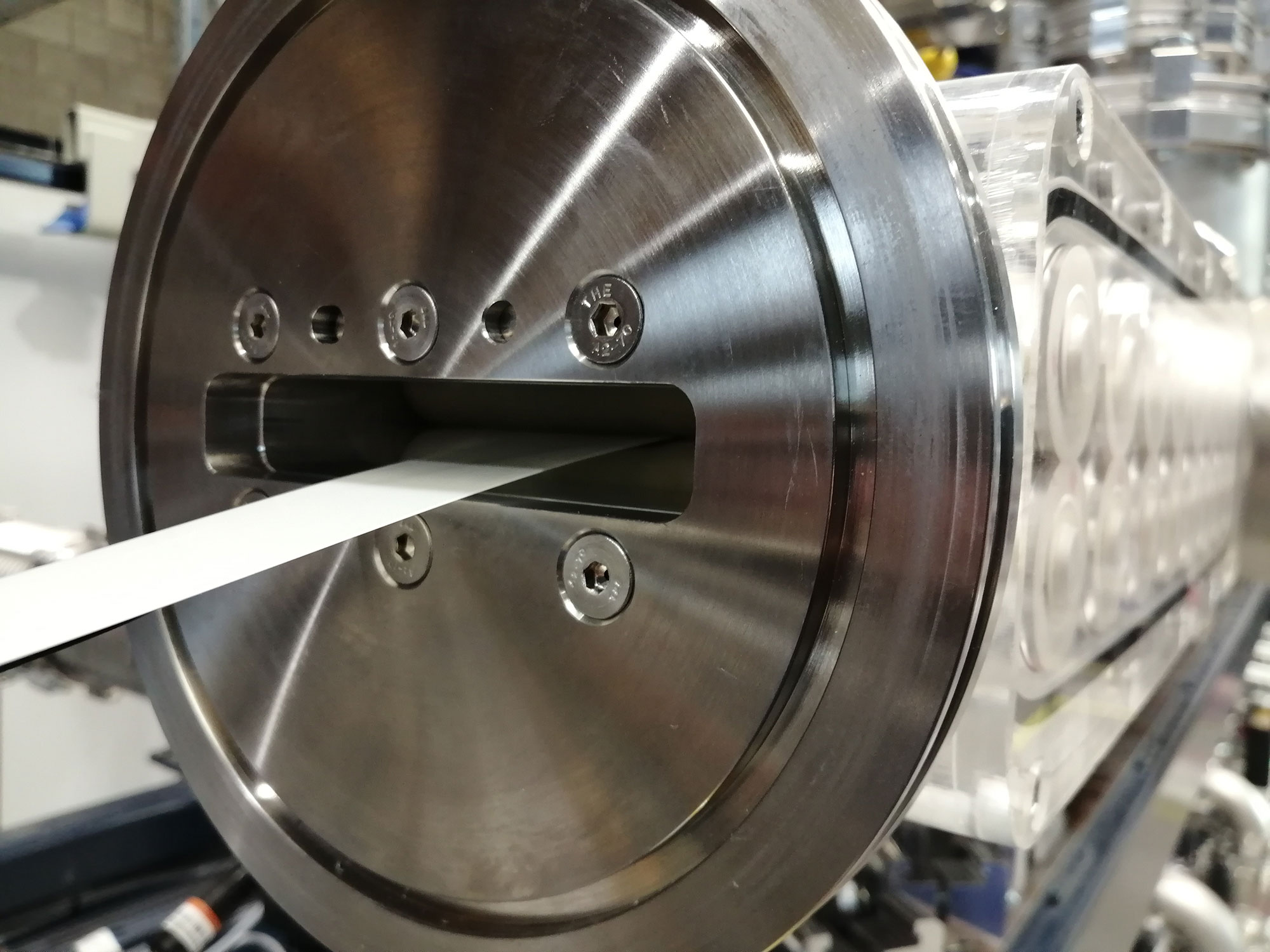

Celebrating one year of successful operation, our ionR2R system continues to make strides in treating connector coils, cables, and metallic strips through ion beam implantation. Operating on an air-to-air, reel-to-reel system, this advanced technology delivers outstanding properties such as hardness, wear resistance, and corrosion resistance. As a result, ion implantation can reduce the gold thickness deposited on connectors by a factor of four while maintaining the highest performance, resulting in significant precious metal savings. |

International market

|

IONICS is thrilled to announce a significant milestone in our global expansion strategy ! We are delighted to introduce our new partner and distributor in Japan: Matsubo Corporation. As we continue to grow and expand our presence in international markets, constructing strong partnership is key to our success. With Matsubo Corporation on board, we are taking a significant step forward in bringing our products and services to the Japanese market. |

Upcoming events

|

Save the date - March 13-15, 2024 - Tokoname in Japan.

Visit us at Smart Manufacturing Summit by the EU-Japan center for industrial cooperation in hall C to discover our innovative solutions in connector and additive manufacturing industry. IONICS will be represented by our AWEX representative, Mr. Olivier DOUHERET

Save the date - March 20-21, 2024 - Berlin in Germany. Join Europe’s user conference on industrial AM Forum 2024 in the Estrel Congress Center and meet our representative, Mr. Robert LAUTH, on site.

|

IONICS turns 10 !

|

We are delighted to mark the tenth anniversary of our company, a decade of achievement, growth and innovation in the field of surface treatments. Over the past ten years, we have met challenges, overcome obstacles and built a strong and successful business. Our employees are the real heroes of our company, and we are grateful for their dedication and invaluable contribution. So, we say to all of you - employees, customers, suppliers and partners – profoundly thank you for having contributed to our success over the last 10 years ! An event will be organised later this year to celebrate this anniversary with you ! The date will be fixed and communicated later, so stay tuned...

|

Strengthening partnerships : ROBEKO's visit

|

We are thrilled to share that ROBEKO, a valued partner of IONICS, visited our company. We had the pleasure of hosting their CEO, Rolf SCHÄFER, who toured our plasma and ion implantation equipment, as well as the electroplating department, which has undergone significant restoration since 2022. We had the pleasure of hosting their CEO, Rolf SCHÄFER, who toured our plasma and ion implantation equipments, as well as the electroplating department, which has undergone significant restoration since 2022. We are honored to have Rolf Schäffer as our guest. Thank you so much for the interesting discussions, to expand collaboration between our companies in diverse fields. |

Our QMS evolution

|

As our IATF certificate approaches its expiration on March 17th, we've chosen a new path forward. Rather than renewing our IATF certification this year, we have decided to revamp our Quality Management System to align with the ISO-9001 format. In this endeavor, we're delighted to offer our customers the option to maintain specific IATF points within the IONICS QMS through the implementation of "quality plans." This proactive approach ensures that we continue to uphold the highest standards of quality and service excellence. |

An excellent job for a student !

|

We're looking for an automation student for our site in Herstal. If you would like to join a dynamic team in a high-tech field, please send your application to IONICS. We look forward to welcoming you to our Engineering department ! See more... |