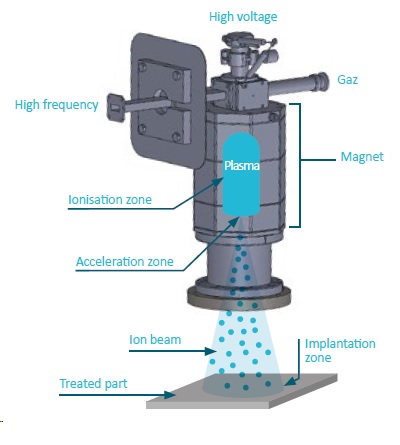

What is an ionGUNTM ?

Since 2017, IONICS has developed a range of low-pressure micro accelerators (ionGUNTM) allowing an efficient and cost-effective use of the ion beam implantation process. An ECR (Electron Cyclotron Resonance) with a dense plasma source produces a multi charged ion beam of up to 10 mA accelerated by an electric field at 35 keV towards the material surface to be treated. Various gases, pure or mixed, are used to enhance surface performances of metal, glasses, ceramics, and polymers. The ion depth penetration depends on the gas, material composition and temperature, initial beam energy and glancing angle. Such ion implantation process enhances surface performances and brings new properties to your material without any added coatings.

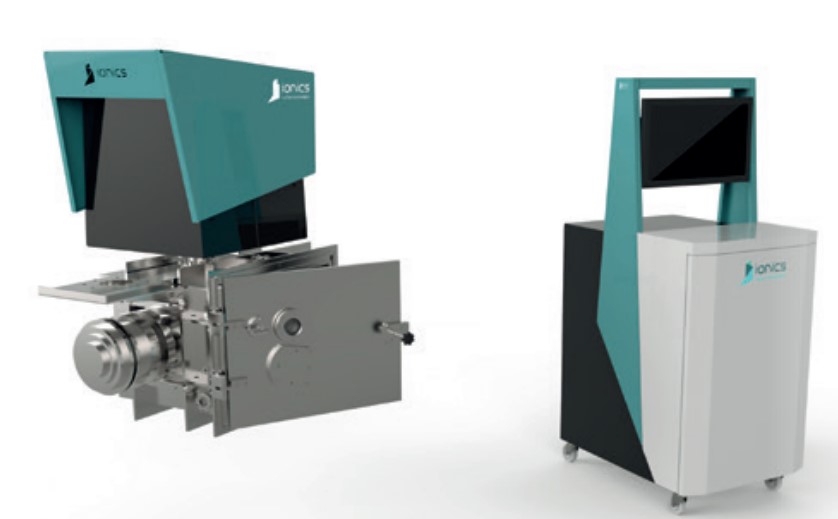

ionGUNTM, ECR ion sources :

ionGUNTM sources are compact and could be easily implemented on existing low-pressure equipment or brand-new systems designed by the IONICS engineering team. Lab scale chambers and specific industrial production lines are available for demonstration. The technology can be combined with other low-pressure technologies like PVD (Physical Vapor Deposition) and PECVD (Plasma Enhanced Chemical Vapor Deposition) processes to enable the production of more performant materials with enhanced properties.