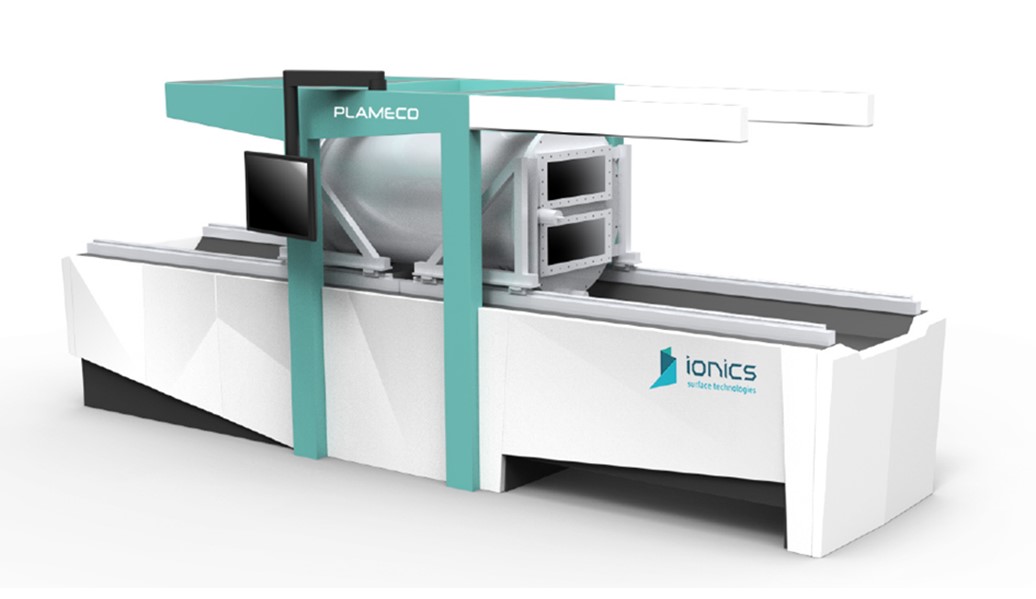

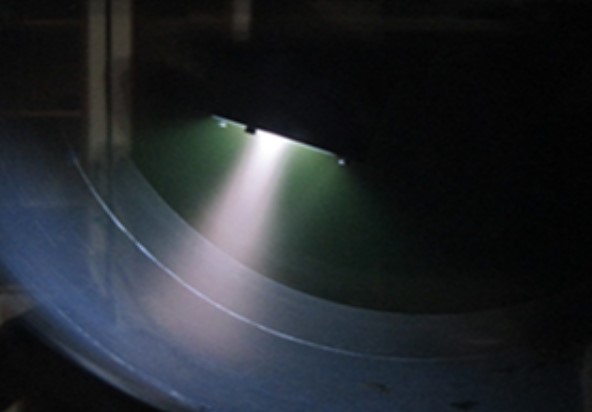

IONICS has developed with MATERIA NOVA’s engineers an innovative low-pressure plasma coating process to treat powders and loose parts. R&D and industrial systems are available equipped with evaporating sources, magnetron or hollow cathodes and even our Hardion ion implantation technologies. Fine tune your system for your application !

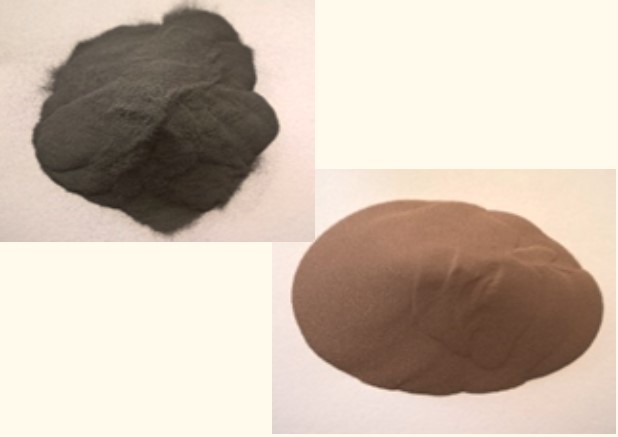

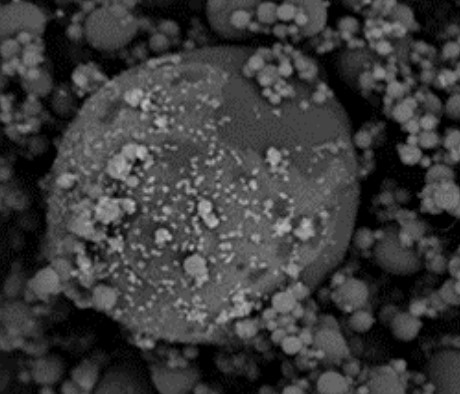

In the field of powders, PLAMECOTM allows to develop new complex alloys, to fine tune compositions, to form core shell structures or to nano structure the surfaces for enhanced processes and final properties. Tailor your powders for your needs modifying any basic commercial materials: polymers, ceramics, metals. The aimed applications are:

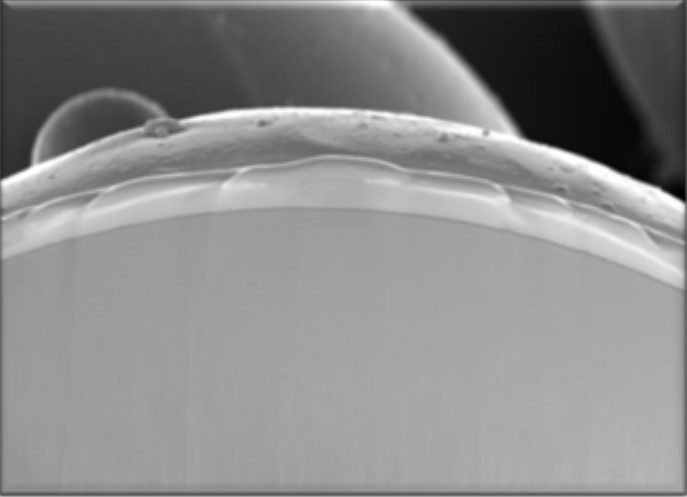

The PLAMECOTM system has also been developed to coat small loose parts as connectors, technical balls, fixing systems with the aim of enhancing wear durability, thermal and electrical conductivity or simply for decoration purposes. Low pressure technologies allow to treat any materials, insulating or thermally sensitive, without wet steps and toxic products. The technology is very flexible and leads to an incredible variety of highly performant coatings.